- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

News

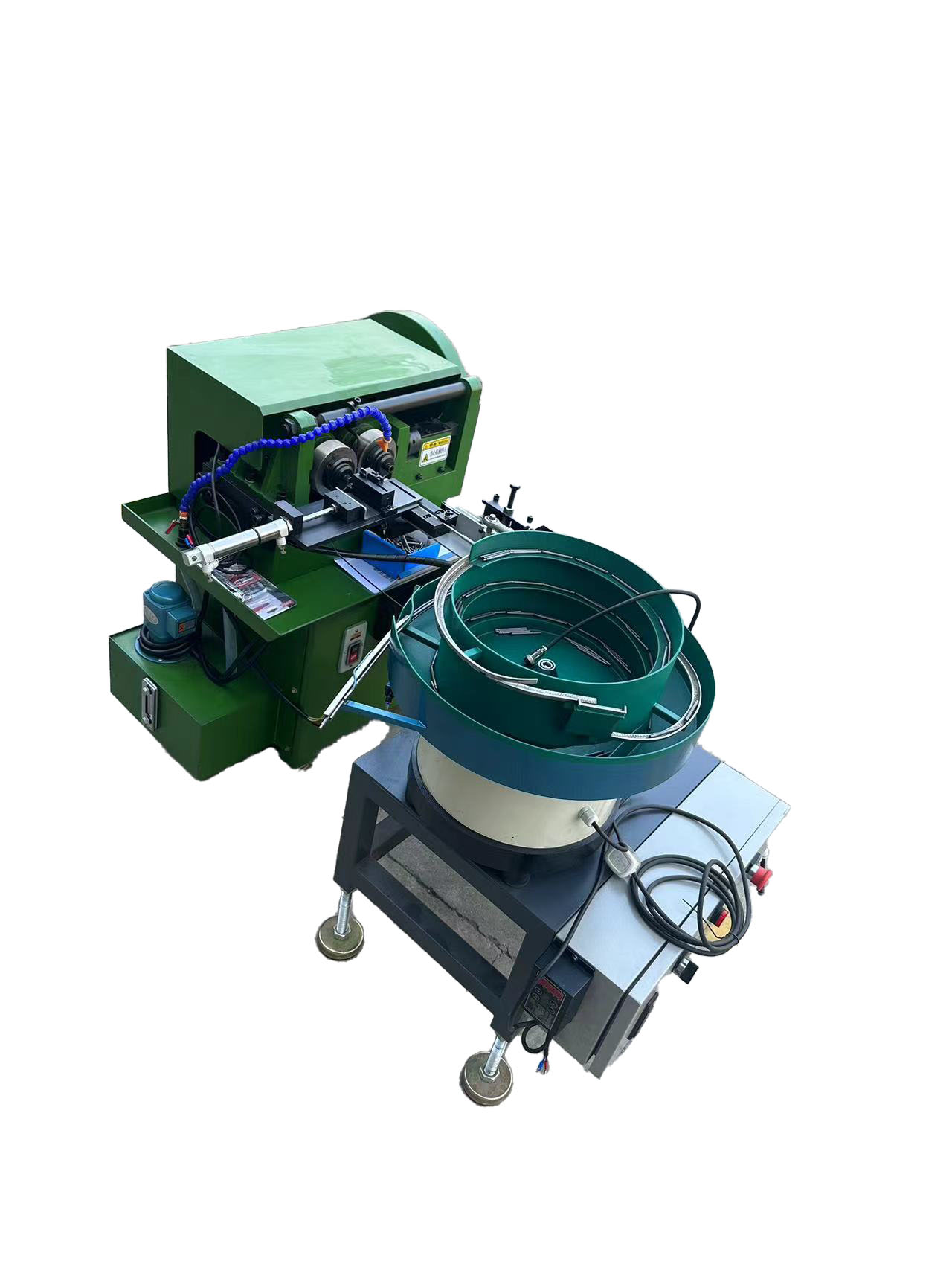

Advantages of eccentric thread rolling machine

The eccentric hobbing machine has exquisite design, simple and convenient operation, and adopts precise eccentric feed to greatly improve the product precision. The products are economical and practical, and can be divided into fixed models and roll-through models, so that customers can choose the ......

Read MoreThree-axis roller to improve production efficiency

With the development of manufacturing industry, more and more enterprises begin to pay attention to how to improve production efficiency and reduce production costs. In this context, three-axis roller machine as an advanced processing equipment, is gradually favored by all walks of life. This articl......

Read MoreCharacteristics and application of high-precision hydraulic tooth roller

High-precision oil-pressure rolling machine is a kind of equipment widely used in machining industry, which is mainly used for rolling teeth, tapping and other precision thread processing. This equipment is driven by oil pressure, which has the advantages of high precision, high efficiency and high ......

Read More